Distribution Industry: Cost Change Challenges & Managing Them

May 9th, 2023 (Updated 06/14/2023) | 10 min. read

As a distribution company, your business faces a unique set of pricing challenges that are specific to your industry. While other organizations may not have to worry about these issues, distributors have traditionally sought to achieve greater scale to expand their profit margins and return on sales through mergers. However, as the opportunities for growth become scarce, some distributors have been hesitant to implement automated and dynamic pricing strategies, considering their cost changes challenges are potentially too complex to manage through automation. Instead, they have relied on their sales teams’ expertise, rather than taking advantage of the invaluable insights offered by modern pricing software.

At Pricefx, we have spent over a decade helping our clients make informed pricing decisions in real-time, specifically tailored to their distribution industry businesses. Our aim has been to help them protect their profits, help them manage their cost change challenges and transform them into agile and cost-effective pricing organizations.

The distribution industry plays a critical role in the economy as it is responsible for the movement of goods and services from producers to consumers. However, the industry faces numerous challenges in managing cost changes, especially in the contemporary business environment. In this article, we will examine the challenges facing the distribution industry in managing cost changes and explore several ways to manage them effectively.

The Distribution Industry: Cost Change Challenges

The distribution industry is currently facing numerous challenges in managing cost changes due to a range of factors, including changes in market demand, increasing competition, rising labor costs, labor availability, and fluctuating fuel prices. One significant challenge for distributors is the need to manage costs while maintaining the quality of service to customers.

Distributors must balance the need to control costs while ensuring timely delivery of products to customers. Failure to manage cost changes effectively can result in reduced profitability, loss of customers, or in the worst-case scenario, possible business failure.

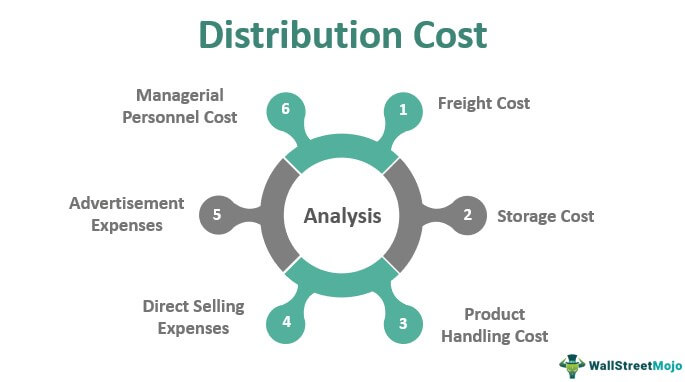

What’s more, distributors face a range of different cost types that are unique to the industry.

The process of distributing a product involves multiple types of costs that a company may incur. Typically, a product is manufactured at a production site such as a factory, and then stored at a warehouse until it is ready to be shipped to potential customers. In order to transport the product from the warehouse to the customer’s location, the producer may need to pay for various expenses, such as shipping fees.

*Image used with permission of WallStreetMojo

These costs encompass all expenditures associated with delivering the product to the customer and are usually recuperated by incorporating them into the per-unit price of the item.

Another challenge facing the distribution industry is the impact of technology on cost management. With the increasing use of technology in distribution operations, there is a need for distributors to invest in new systems and software to manage costs effectively. This investment can be expensive and require significant resources, making it a challenge for smaller distributors with limited resources.

8 Tips for Managing Cost Changes in the Distribution Industry

To manage cost changes effectively, distributors must adopt a range of cost management techniques that consider and address the unique challenges facing their business. Here are 8 tips to efficiently manage cost changes in the distribution industry:

1. Implementing a Pricing Strategy

One way to manage cost changes is to implement a pricing strategy that considers market demand, competition, and cost structure. A pricing strategy can help distributors maintain profitability while remaining competitive.

For instance, a distributor can use dynamic pricing to adjust prices based on changes in market demand, such as peak periods or low-demand seasons.

Alternatively, some distributors may offer quantity discounts to customers who purchase large volumes of a product. This pricing strategy can be used to incentivize customers to purchase in bulk, which can reduce distribution costs per unit. However, distributors must carefully consider the discount rate to ensure that they are not losing money on larger orders.

Some distributors may need to consider zone pricing, whereby different prices are set for different geographic regions. Distributors may use this strategy when shipping products over long distances, where transportation costs can vary widely based on distance.

By setting different prices for different zones, distributors can ensure that they are covering their transportation costs while also remaining competitive in each market. However, they must consider the impact of this strategy on customer perceptions of fairness and consistency in pricing.

2. Investing in Technology

Investing in technology can help distributors manage costs effectively. For example, distributors can use automation technology to reduce labor costs and improve efficiency in warehouse operations.

Additionally, using transportation management systems (TMS) can help distributors optimize shipping routes, reduce fuel costs, and improve delivery times.

(We will discuss pricing software technology specifically later in this article).

3. Outsourcing

Outsourcing some operations can be a cost-effective way for distributors to manage cost changes and reduce labor costs, transportation costs, and warehouse expenses.

For distributors, outsourcing transportation services to third-party logistics providers (3PLs) or using a third-party warehouse to store and manage inventory can be an effective way to help manage these challenges.

By using a 3PL, distributors can leverage their expertise and resources to optimize transportation routes and reduce costs, while also improving delivery times and customer satisfaction.

Similarly, using a third-party warehouse can help distributors manage inventory levels and reduce the cost of maintaining their own warehouse facilities. This approach can be especially beneficial for distributors that experience seasonal fluctuations in demand or unpredictable changes in transportation costs.

By outsourcing these services, distributors can focus on their core competencies and better manage their costs, ultimately leading to improved profitability and competitiveness in the market.

4. Analyzing Costs

Analyzing costs is an essential aspect of cost management. Distributors must identify the main cost drivers and analyze how changes in these costs affect profitability.

Regional distributors or distributors with little product differentiation in their offerings can possibly get away with using tools such as cost accounting software or even Excel to analyze costs and identify areas where cost savings can be made.

Larger distributors with more complex product and customer segments may need to use pricing software to fully analyze their costs and plug their margin gaps, which we will discuss below.

5. Negotiating with Suppliers

Negotiating with suppliers can help distributors manage cost changes by reducing the cost of goods sold.

Distributors can negotiate better terms, such as volume discounts or longer payment terms, to reduce costs. Additionally, distributors can consider working with suppliers to reduce transportation costs by consolidating shipments or using more efficient modes of transportation.

6. Improving Inventory Management

Inventory management is critical in managing cost changes in the distribution industry. Poor inventory management can result in excess inventory, which ties up cash flow and increases storage costs.

Improving inventory management can help distributors reduce inventory costs and optimize supply chain operations.

At the risk of sounding like a broken record, automated pricing software can assist in improving your inventory.

Pricing software can be an invaluable tool for distributors in the distribution industry to optimize their inventory management and reduce costs. For example, a distributor of electronic components may use pricing software to track changes in market demand for specific products and adjust prices accordingly.

By leveraging this software, the distributor can identify which products are selling quickly and which are not, allowing them to adjust their inventory levels accordingly.

This can help to minimize the cost of storing and managing inventory, while also ensuring that the distributor has the products on hand to meet customer demand.

Additionally, pricing software can help distributors to identify and respond to changes in market conditions, such as increased competition or shifts in customer preferences. By adjusting prices in response to these changes, distributors can improve their competitiveness and maintain profitability, while also minimizing the risk of overstocking or understocking inventory.

7. Streamlining Operations

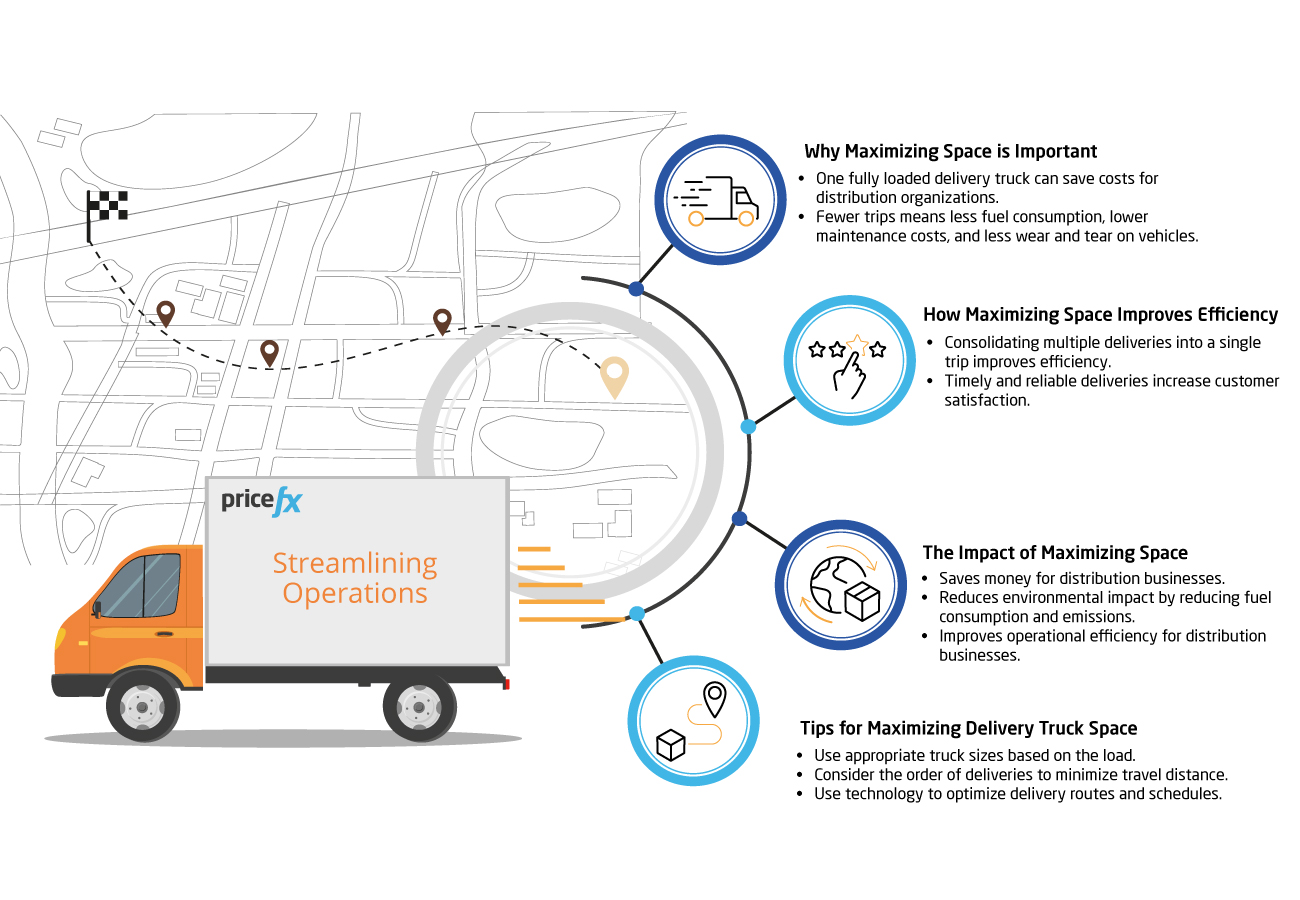

Streamlining operations can help distributors manage cost changes by reducing waste and improving efficiency. Distributors can use lean principles to eliminate waste in warehouse operations, such as excess inventory, overproduction, and unnecessary motion.

For example, sending out one delivery truck that is fully loaded for a single delivery run can make a significant impact on the cost savings for a distribution organization.

By maximizing the space in each delivery truck, distributors can avoid unnecessary trips and reduce transportation costs. This approach can also help to reduce fuel consumption, maintenance costs, and wear and tear on the vehicles.

Furthermore, by consolidating multiple deliveries into a single trip, distributors can improve their efficiency and increase customer satisfaction by ensuring that deliveries are made in a timely and reliable manner.

The benefits of fully loading delivery trucks instead of half-empty ones are clear: it saves money, reduces environmental impact, and improves operational efficiency. It is a simple but effective strategy that can have a significant impact on managing costs for a distribution business.

Additionally, distributors can use process automation to reduce manual labor and improve productivity.

8. Using Pricing Software

If you are this far through the article, you have already read several examples of how pricing software can assist your distribution business in managing its cost challenges. But there are more ways that pricing software can be a valuable tool for distributors facing the challenges of cost change problems.

With the help of pricing software, distributors can quickly adjust their prices in response to changes in costs, such as increases in raw material prices or changes in transportation costs.

This allows distributors to maintain profitability even in the face of cost fluctuations, as they can adjust their prices to reflect the new cost structure. Pricing software can also help distributors identify areas where costs can be reduced, such as by optimizing delivery routes or consolidating shipments, further improving profitability.

In addition to cost change problems, pricing software can also help distributors find profitable solutions by analyzing customer data and market trends. By identifying which products are in high demand and which are not, distributors can adjust their pricing strategy to focus on profitable products and reduce prices on less popular items. This can help distributors increase sales and improve their margins. Pricing software can also provide real-time data on competitor pricing, allowing distributors to adjust their prices in response to changes in the market.

Overall, pricing software can be a powerful tool for distributors looking to navigate the challenges of cost change problems and find profitable solutions in a rapidly changing market.

Discover How to Use Pricefx to Manage Your Cost Change Challenges

Now you know a range of methods to manage your distribution organization’s costs, you may be looking to drill down into the specifics of how an automated pricing software solution like Pricefx can help you manage those annoying and rampant cost fluctuations.

Check out this handy article below to learn the top features Pricefx software boasts specifically for a distributor like you:

Or if you still analyzing your pricing solutions options, learn more here about how to choose the best pricing software for your business.

Happy Pricing!