For manufacturers like yourself, managing complex customer and product portfolios profitably while navigating today’s market uncertainties and unrelenting global competition demands data-driven sales decisions; not only to safeguard your position at the top, but also to reach even greater heights in the future.

Here at Pricefx, as a leading pricing software vendor, we’re big believers in data as a facilitator of more informed choices and lasting impact in organizations, with sales teams among the first stops for driving that change. So, how can manufacturing sales teams use data to drive more efficient, and ultimately more fruitful, negotiations?

In this article, we’ll impart your manufacturing company with a few fail-proof strategies for making better sales decisions with data – empowering your sales teams to enable shorter sales cycles, more valuable deals, and ultimately, more profitable pricing decisions for your company.

Sound good? Let’s jump right in!

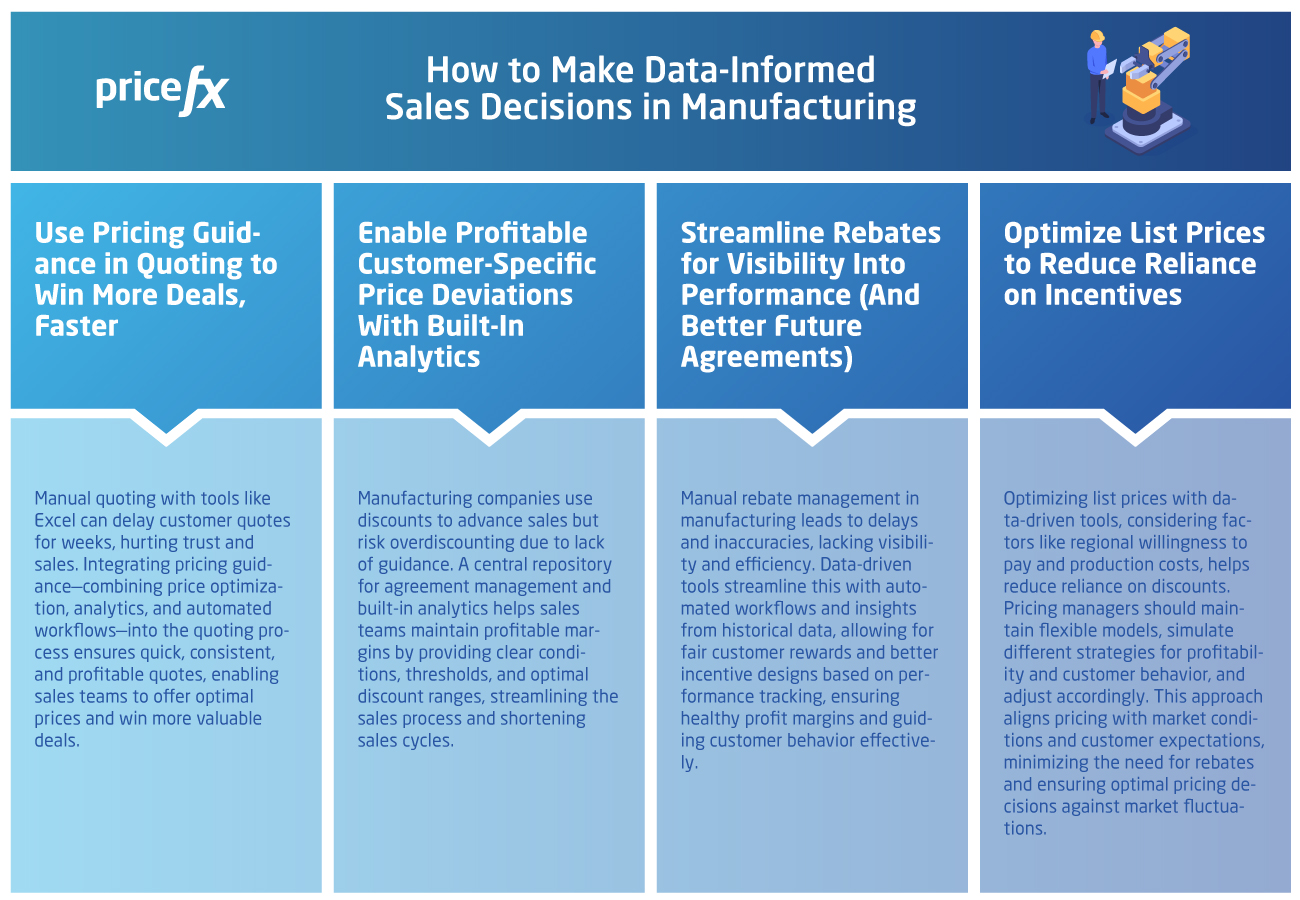

4 Ways for Making Data-Driven Sales Decisions in Manufacturing

1. Use Pricing Guidance in Quoting to Win More Deals, Faster

When quoting with manual tools such as Excel spreadsheets, a quote can take upwards of several weeks to finalize, resulting in delayed quotes to customers. Delays in the quoting process compromise trust in long-term partnerships, and at worst, can push prospective distributors or retailers to turn to a smoother buying experience with a competitor.

But apart from drawing out sales cycles and frustrating would-be and current customers, manual quoting also prevents your sales teams from selling at optimal prices in line with the company’s pricing strategies, the market reality, and customer value perception.

Here’s where integrating pricing guidance into your quoting process would help. Pricing guidance in quoting refers to connecting a few data-driven pricing features – namely price optimization, analytics, and automated workflows – to a quoting solution to ensure consistency and profitability on every quote in the selling stage.

A quoting solution with built-in pricing guidance allows sales reps to navigate negotiations confidently with data-driven price recommendations, including stretch, target, and floor prices, and their impact on profitability. And, instead of guessing in the dark, a sales rep can immediately recognize if an option for a quote meets financial targets, and if not, an automated workflow in the system will route the exception for approval, in effect mitigating approval delays and constant follow-ups.

Leveraging pricing guidance in the quoting process enables sales teams to process quotes quickly and intuitively. And it’s important that this guidance is defensible, which is why it gets input from the sales team themselves. With pricing analytics backing their quoting decisions, sales reps can consistently offer optimal prices and, in turn, facilitate more valuable won deals.

2. Enable Profitable Customer-Specific Price Deviations With Built-In Analytics

In most manufacturing companies, where moving substantial amounts of product at a time is commonplace, discounts are a valuable tool to push sales negotiations forward. However, in efforts to make the offer more appealing or strengthen the commercial relationship, sales reps may unwittingly set a precedent of overdiscounting in the long term.

Offering a discount beyond what’s profitable is often the result of a lack of sales guidance and visibility into agreement conditions.

As a baseline, a repository for agreement management enables sales teams to define and view all of the relevant conditions and surcharges for agreements, such as discount thresholds and eligibility criteria, to which they can later return to replicate or adjust when renewals come around. Additionally, built-in analytics offer sales teams guidelines to reference for each customer agreement in the form of suggested stretch, floor, and target percentages for discounts.

By having a central tool for storing agreement conditions and immediate access to analytics for optimal discount ranges, manufacturing sales teams can maintain profitable margins on the various products coming in and out, while also enjoying a streamlined process that contributes to quicker sales cycles.

3. Streamline Rebates for Visibility Into Performance (And Better Future Agreements)

Manual rebate management in manufacturing can often lead to delayed payouts to customers, with accrual and payout calculations typically requiring entire teams, several weeks of effort, and lots of documentation for reconciliation. Without a central mechanism for calculating and tracking progress, a manual approach can both result in frequently inaccurate (and often overly generous) payouts and low visibility into how well rebates accomplish their goals.

Data-driven tools for rebate management don’t just enable a more streamlined process with automated approval workflows and payouts, capabilities that sales executives can use to set up and renew agreements more efficiently, but also improve future versions of your incentive programs using insights from your historical data. Without incorporating historical data into this process, teams will likely struggle to tap into what has and hasn’t worked in the past in guiding the right customer behaviors and maintaining healthy profit margins.

Sales teams should have visibility into performance over time, both to ensure that customers are rewarded fairly for their efforts, and , if customers continually fall short of expectations, that rebates are more optimally designed to incentivize the right behaviors in the future.

4. Optimize List Prices to Reduce Reliance on Incentives

Beyond setting up effective incentivization structures, optimizing list prices to reduce the need for discounts and rebates in the first place is key.

With data-driven tools to incorporate into pricing factors like customer willingness to pay across regions and products, direct material and labor costs, and overheads like machinery depreciation and factory repairs, sales teams can avoid falling into the habit of over-discounting to drive sales.

To effectively price products to account for these disparate factors (and avoid reliance on incentive programs), pricing managers in manufacturing should maintain flexibility in their pricing models. To do that, instead of employing a one-size-fits-all pricing approach, pricing managers can simulate the impact of different pricing strategies on profitability, sales volume, and the behavior of individual customer segments (a specific customer, product, or region combination) and adjust their strategies accordingly.

With price optimization tools, businesses can bring pricing and sales teams together by offering prices that are well received by customers and accurately reflect market conditions, pulling back on their historical reliance on discounts and rebates. Armed with optimized list prices, manufacturing companies can ensure their entire organization makes optimal pricing decisions in negotiations in the face of fluctuating market forces.

Want to Know How Pricefx Makes It Happen?

In this article, we’ve offered up a few tips on how manufacturers like yourself can use data-driven solutions to maximize sales efficiency, secure more profitable deals, and mitigate margin erosion in the long term. And the best part? These strategies are within reach with pricing software solutions.

Curious to discover how? For an in-depth account of how enterprise pricing software supports data-driven sales decisions in the manufacturing industry, head to our article that outlines how Pricefx helps: