How to Manage Supplier Costs for Distributors With Pricefx

April 2nd, 2024 | 7 min. read

Distribution companies occupy a unique position in global supply chains that complicates their supplier cost management process. As the link between manufacturers, wholesalers, and retailers, and not typically producers or final sellers of goods themselves, distributors rely on suppliers to communicate their costs to make pricing decisions of their own. Given that profitability largely hinges on these costs, how can distributors ensure that they manage supplier costs effectively and enable prices that both cover expenses and enhance margins?

At Pricefx, as a leading enterprise-level pricing software vendor with distribution among the core industries we serve, we’ve developed solutions that address the unique challenges in the industry, and supplier cost management is one area that can especially benefit from the automation our pricing solutions offer.

In this article, we’ll break down how Pricefx can help your distribution company to streamline its supplier cost management process, improve visibility into and responsiveness to margin-eroding costs, and ultimately, enable consistently profitable pricing decisions in the face of frequent cost fluctuation.

What Makes Supplier Cost Management a Challenge in Distribution?

As an intermediary between manufacturers and retailers, distributors are heavily reliant on supplier costs for their own pricing, taking the purchase costs from their suppliers to then add their own freight, storage, and other fees, such as carrying costs. The cost they have built generally becomes the cost basis for the final resale.

Under normal circumstances, suppliers communicate their costs to distributors on a semi-regular basis, which are then manually updated in price lists.

However, when supplier costs for products naturally shift over time, these adjustments can be difficult to track if they happen frequently or unexpectedly – normally in response to market shifts, freight costs, and other volatile factors. In time, this variability in supplier costs eventually gives way to thousands of products on the shelves, all with different costs, that make margin calculations a difficult, if not impossible, task.

Due to the complex and often irregular nature of supplier costs in distribution, distributors require a streamlined supplier cost management process that allows them to price goods to both cover the various cost factors across supply chains and to make profitable markups of their own.

How Pricefx Helps With Supplier Cost Management & How Distributors Benefit

In this section, we’ll highlight a few Pricefx capabilities that provide distributors with solutions to the challenges they encounter every day in their industry when trying to manage supplier costs profitably. In a few words, these include:

- Blended cost calculations for on-shelf products to leverage for more accurate profit margin calculations

- Automated price re-calculation based on new supplier cost information and syncing to third-party systems like ERP

- Automated cost approval workflows built into costing grids for increased visibility and quick reactivity to margin-draining cost elements

Please note before we begin that the benefits mentioned in this article are the result of configuration and are thus unique to each distributor.

With that, let’s dive into specifics.

1. Blended Cost Calculation for Current On-Shelf Products

When distributors leverage manual systems to manage supplier costs, they often lack the visibility to calculate a uniform cost across their on-shelf products to set their own markups. With thousands of SKUs in inventory at different cost points, those established margins are likely lower than they should be, leading to compromised profitability and missed opportunities to capture revenue.

To address this, cost admins can use Pricefx to pull in the costs for products currently on shelves and calculate their blended cost (i.e., the weighted cost average), enabling them to calculate margins based on a single representative cost.

With a tool to easily calculate blended cost of their inventory, distributors can set up more accurate markups that factor in the variable costs of their on-shelf products as well as leave room to profit themselves. And, by averaging out supplier costs rather than treating them separately, distributors can establish a healthier precedent that sets up their prices to be less impacted by heavy cost deviations in the future.

2. Automated Cost-Based Price Recalculations & Syncing to Third-Party Systems

When distribution cost managers use manual methods to update price lists with the latest supplier cost information, their price re-calculations are often slow going, giving way to delayed or error-ridden pricing that disregards the present market reality. What’s worse, margin compression is an all-too-common consequence when out-of-date pricing is the norm.

Bringing automation to price updating supports a quicker price re-calculation process and, more importantly, ensures that prices stay competitive and in line with the latest supplier costs.

Once a cost manager sets up an initial re-calculation logic that considers the relevant cost drivers, price changes are instantly triggered in price lists when new supplier costs come in. Our platform’s integration with third-party systems ensures that cost-based price updates are always reflected in ERP and other connected systems.

With price adjustments calculated and reflected in their third-party systems in real time, distributors can account for ad hoc supplier cost fluctuations in their pricing without worrying about persistent error or margin erosion, ultimately supporting healthier margins overall.

3. Automated Supplier Cost Approval Workflows in Costing Grids

In distribution, where supplier costs often fluctuate without prior notice, a manual cost approval process often serves as an obstacle to up-to-date pricing, calling into question the accuracy of price lists overall. If, by the time one set of costs is approved, another set becomes current in the meantime, to consider the resulting prices as reliable becomes a challenge.

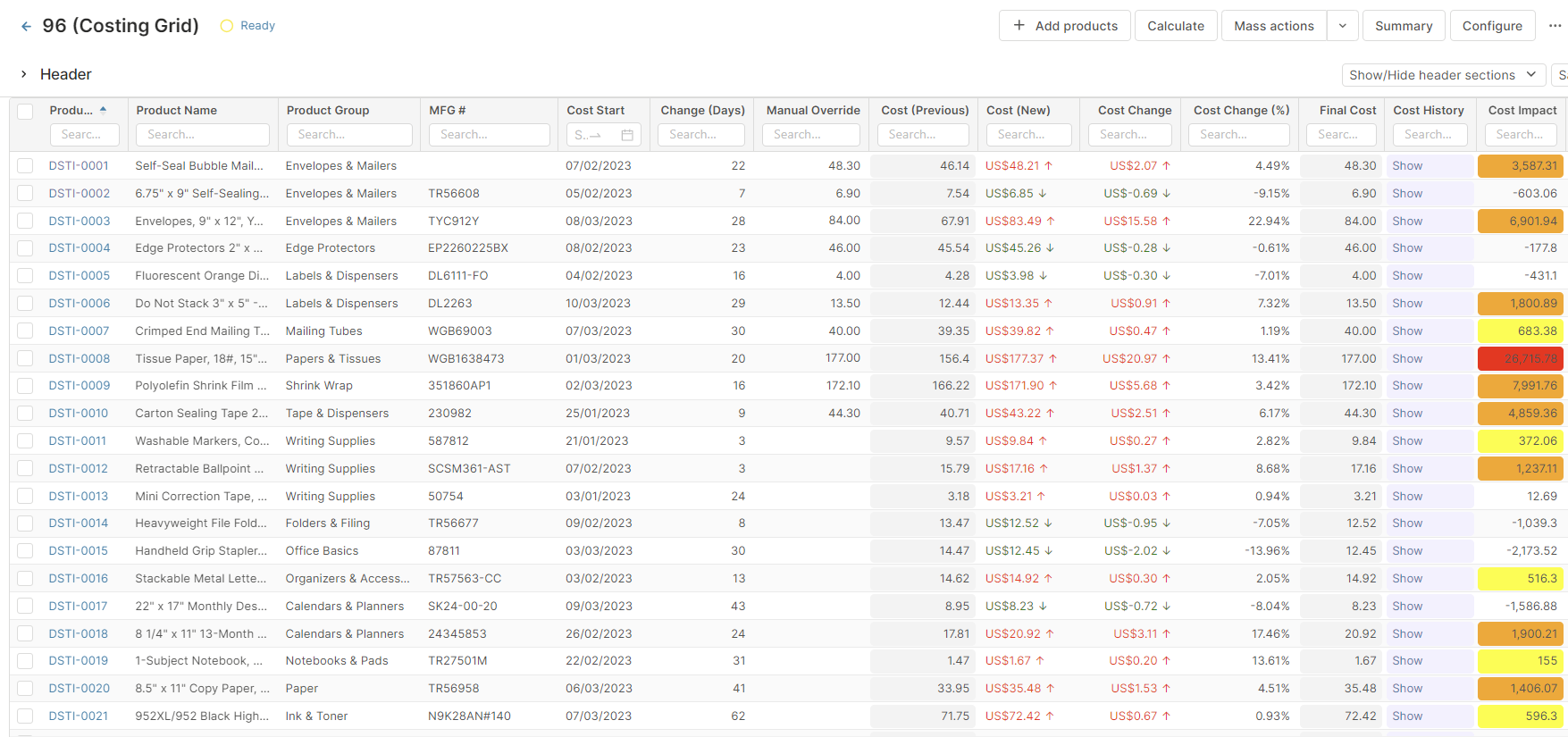

With Pricefx, distribution companies can automate the cost approval process by embedding their workflow logic, including approval tiers and assigned roles, directly into the solution. This integration is available in our Costing Grids, an interface that provides costing managers with a comprehensive view of a wide range of cost elements across products, including historical and present costs, cost change velocity over time, and cost impact.

In Costing Grids, cost managers can define approval logic according to the severity of cost impact. For example, a product demonstrating a modest degree of (negative) impact on profitability might simply require a manager’s approval, while higher levels of impact might require a director and a VP’s approval. Cost managers can quickly identify the line items that require attention through an intuitive visualization of impact levels in which each level is assigned a different color.

To support more efficiency in the process, costing managers can also mass approve costs or mass route them for approval. And, for greater accountability and visibility in the approval process, pending approval items can be tracked by other members with an “add watchers” feature.

Easily customizable and automated cost approval workflows not only support more efficient and agile approval processes, but also offer visibility into areas of supplier costs that may erode margins, allowing for immediate action.

How Pricefx Helps Your Distribution Company With Price Management

By now, we hope we’ve left you with a clearer picture of how Pricefx supports distributors like yourself in streamlining its supplier costs to facilitate more optimal outcomes. From automating approval workflows and price lists for efficient and up-to-date pricing, to harmonizing costs for accurate margin calculations, our solutions are designed to alleviate the challenges that come with supplier cost management in distribution.

This article highlights a fraction of the ways that Pricefx solutions enable distributors to manage their pricing more profitably. Want the full picture? Consider heading to our article below: